Overview of Dental Milling Machines

Dental milling machines are must-have instruments aimed at the dental sector. Their main task is to help manufacture consistent prosthetic restorations. Designed to serve the needs of the dental sector, these devices use the principles of both CAD and CAM to cut a range of dental materials into crowns, bridges, etc. That is, their main purpose is to provide more accurate, quick, and efficient ways to produce these items and guarantee that the patients will obtain qualitative implantations fitting their bodies and meeting their aesthetic demands.

Dental milling machines have come a long way over the years. At first, the milling was purely manual meaning it was slower and less accurate. Since the advent of digital technology, the process of creation of different dental prosthetics has been taking an entirely different trajectory. That aside, the precision that comes with some of the innovations makes it possible to work on even the most challenging shapes with little human control. Besides, the efficiency of the modern milling machines is enhanced by features like high speed spindles, better tools, and software systems.

There’re different types of Dental milling machines, each of them serving their own unique purpose. Some are more focused on being able to effectively use with harder materials, and some on softer ones. One common type is dry up milling machines, used for materials such as ceramics. Wet milling machines are designed for using with the material that needs to be cooled down during the process of milling, which includes a wide range of different composites in most cases. Knowledge of various milling machines available to the dental expert is needed to ensure an optimal workflow and patient satisfaction.

DentalXangTech’s Product Offerings

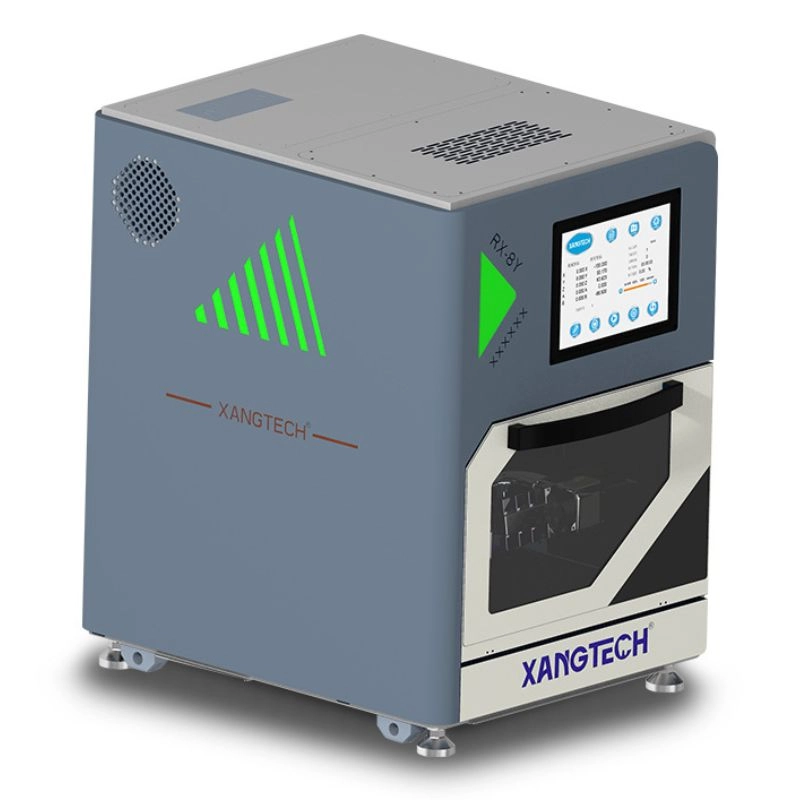

DentalXangTech offers a comprehensive range of dental milling machines designed to meet the diverse needs of dental professionals. Their machines are known for their cutting-edge technology and user-friendly interfaces, enabling practices to seamlessly integrate them into their operational workflows. Product offerings include options for various material types, such as RX-8Y Milling Machine, along with accessories that enhance productivity and versatility. This selection allows dental professionals to tailor their equipment choice based on specific practice demands and patient needs.

Types of Machinable Materials for Dental Milling

Commonly Used Materials

Zirconia

Zirconia is one of the most popular machinable materials in modern dentistry due to its excellent mechanical properties. This ceramic material exhibits remarkable strength and high resistance to wear, making it an ideal choice for fabricating long-lasting dental restorations. Zirconia can also be processed to achieve a lifelike aesthetic, blending seamlessly with natural teeth, which is particularly advantageous for cosmetic applications.

PMMA (Polymethyl Methacrylate)

PMMA, or polymethyl methacrylate, is another widely-used material in dental milling. This polymer is known for its versatility and ease of use, particularly in the creation of temporary restorations. PMMA materials are lightweight, durable, and can be easily adjusted to accommodate patient-specific anatomical features, making it a preferred choice for provisional crowns and bridges.

Wax Blanks

Wax blanks are commonly utilized in the dental industry primarily for creating patterns for casting processes. These materials are favored for their ease of milling and ability to produce precise shapes without putting significant strain on milling tools. Wax patterns can be quickly fabricated and modified, allowing for a flexible workflow in the production of dental prosthetics.

Advanced Materials

Titanium

Due to excellent biocompatibility and a high strength to weight ratio, titanium slowly gains the status of an advanced material for dental implants and frameworks. Modern dental implantology may benefit from a durable, long-lasting device if titanium is milled properly. With that in view, it is rather important for dental professionals to be aware of the peculiarities of such material.

Cobalt-Chromium Alloys

Cobalt-chromium alloys have emerged as a common material for manufacturing dental restorations requiring high strength and corrosion resistance. Because of their characteristics, these alloys are particularly ideal and advantageous when used to make fixed denture or partial frameworks. However, milling cobalt-chromium metals demands highly specialized milling machines with suitable tools.

Popular Machinable Materials in Dental Milling

Ceramic-Based Materials

Ceramic-based materials are frequently used for dental milling because of their great esthetic qualities and functionality. It is important to note that these materials are translucent, just like human enamel, properly simulating their natural appearance. This is essential for the creation of parts that are visible to a person. The advantages of ceramics include their resistance to abrasion and the reliable preservation of color over time.

The most common types of ceramic materials utilized in dental milling are zirconia and lithium disilicate. Zirconia is particularly strong and is primarily used for frameworks and posterior crowns. Lithium disilicate is slightly weaker but has great aesthetic properties. Therefore, it is generally used for anterior restorations, where the main focus is on the appearance of the dental matter. The different types of ceramic materials allow dentists to choose the most appropriate solutions for various clinical cases.

Metal-Based Materials

Moreover, metal-based materials are also widely used in dental CAD/CAM technology. They have a plethora of properties and applications, from offering jaw strength and functionality as well as high durability to providing biocompatibility. Metals, such as titanium and cobalt-chromium alloys, serve many restorative and other processes due to their mechanical properties.

While titanium is considered for being lightweight and strong, which makes it an effective material for dental implant fabrication, cobalt-chromium alloys offer improved strength and wear resistance, which can also be utilized to make frameworks and crowns. However, the choice of materials is largely determined by clinical requirements, as well as by the balance between strength and dental aesthetics.

Polymer-Based Materials

Polymer-based materials also can be in milling dental appliances. It has some benefits, which are suitable for certain applications. Material of such type usually have high processability hence, the ability to design complicated appliances and easy process during production.

The common types of polymers that are used in dental milling are polymethyl methacrylate and polyether ether ketone. PMMA is used frequently for the temporary restoration and the denture base, mainly because they are aesthetic and they are low cost. PEEK however is known for their biocompatibility and their mechanical capability, thus they can be used as a dental restoration in the long-term. The use of polymers has been growing, providing additional options for dentists when deciding on ways to realize the specific functional or aesthetic solution.

Innovations in Machinable Material Technology

Advances in Material Science for Dental Applications

Technological progress in the dental application field has resulted in considerable growth in materials science, specifically in the fabrication of machinable materials for the dental milling machine. Thus, materials with better mechanical properties, wear resistance, and biocompatibility are being developed. They play a crucial part as their application requires not only a tight fit but also attainment of functional characteristics enough to accommodate the oral cavity’ formidable workload.

For example, it could be possible to talk about advanced ceramics that unite the aesthetic with the mechanical aspect. In particular, currently, it is possible to observe the development of enhanced zirconia products which are characterized by higher translucency and lower opacity enabling the manufacturers to imitate the natural dentition more accurately. Moreover, studies have resulted in the creation of hybrid materials that can incorporate the positive properties of both ceramics and polymers. As a result, the flexibility of these materials improved significantly combined with their resistance to chipping. In this way, it is possible to argue that healthcare practitioners can use the products that are designed in accordance with the requirements of the contemporary dental practice.

On the other hand, manufacturers have started using additive manufacturing in order to create geometries that are extremely complex or impossible to mill. Many dental restorations today are on the horizon because they are custom manufactured for the patient to fit perfectly. More and more developments in material science will make the work of dental laboratories more efficient. The dynamic functions of modern dental milling machines provide patients with improved results.

Impact on Clinical Outcomes and Treatment Quality

The ability to achieve high degrees of precision in machinable materials is a significant benefit for the field of dentistry. As dental milling machines become more precise, engineers and manufacturers can develop materials that can achieve tighter and more accurate fits for prosthetic restorations. Reduced adjustments and chair time create a better patient experience, reduce the amount of discomfort that the patient might feel, and enhance the quality of treatment.

Additionally, the implementation of materials with better strength features results in longer-lasting restoration. For example, while used as a framework for complex dental restorations, cobalt-chromium alloys are much better in their durability, which is vital for contemporary patients. Correspondingly, individuals receive an extensive number of restoration options that not only look natural but are also capable of enduring the functional stress of day-to-day activities.

The utilization of high-tech materials in the manufacturing of dental restorations can simplify the process and allow more efficient treatment solutions to be applied. Moreover, if clinicians are confident in the longevity and strength of items they produce, patients may also have increased satisfaction with their treatments. The quality of treatment is essential not only for the safety and comfort of patients but also for the sustainability of dental practices, as higher reputation of a given place and a higher rate of treatment success results in more clients.

Application Techniques for Efficient Milling Processes

Best Practices for Preparation and Handling

Optimal results during the milling process depend on the correct preparation and efficient handling. The preparations must be followed by the dental practitioners or technicians to ensure that the machinable materials are in place. These preparations include handling the machinable material and placing them in the milling machine. Before a machinable material is accepted for the working process of the milling machine, the machinable material should go through inspection to ensure it is not defective. Also, the machinable material must conform or be close to the specifications provided. Level of cleanliness of the machinable material is another aspect that must be observed. It should be taken to the milling machine with a lot of care. The preparation should ensure that the machinable material is stored in a clean place, must be the right thickness, and must be stored to avoid contamination. If the machinable material has a holder it must be used accordingly.

It is also necessary to realize that, in the milling process, the implementation of proper cutting technologies and parameters related to a particular material and its properties is crucial. For instance, in case ceramic materials are used, spindle speed and feed rate should be adjusted to facilitate material chipping and increase the tools’ life. A well-defined preparation protocol ensures that milled components reflect a required accuracy level and eliminates waste that can be attributed to mishandling or improper setup.

Integration with Digital Workflows

The integration of dental milling machines with digital workflows has been a game-changer for modern practices. Digital impressions and 3D scanning technologies create accurate representations of patient anatomy, which are then fed into the milling machines for custom restorations. This digital synergy reduces human error and significantly shortens the time needed for creating dental applications. The seamless communication between various digital systems ensures that the workflow is smooth, reliable, and efficient, allowing practitioners to focus on patient care rather than manual adjustments.

Summary of Key Insights on Dental Milling Machines

Understanding the specifics of dental milling machines and materials that they can process is one of the primary factors that can be vital for increasing the quality of clinical results and treatment. Innovations related to machinable material technologies have been developed and implemented into practice. The main benefit is that these dental machines are capable of processing new restorative materials that are more accurate in meeting the functional and aesthetic needs of patients.

High efficiency and reliability when it comes to milling processes require preparation, calibration, and maintenance best practices. The quality of output cannot remain high or even keep up if common problems are not effectively recognized and dealt with. As new technologies and millable materials become adopted in the dental field, clinicians and technicians should remain vigilant for ways to incorporate these novelties and make their practices more successful.

Dental milling machines are not just instruments; they show the connection between technology and care for the patient, how science may improve quality and patient experience.