Menu

Menu

Zirkonzahn milling burs are diamond coated, high-quality milling burs for the efficient production needs of modern dental laboratories and clinics. 100% compatible with Zirkonzahn cad cam milling machine. Zirkonzahn milling burs are suitable for glass ceramics wet grinding.

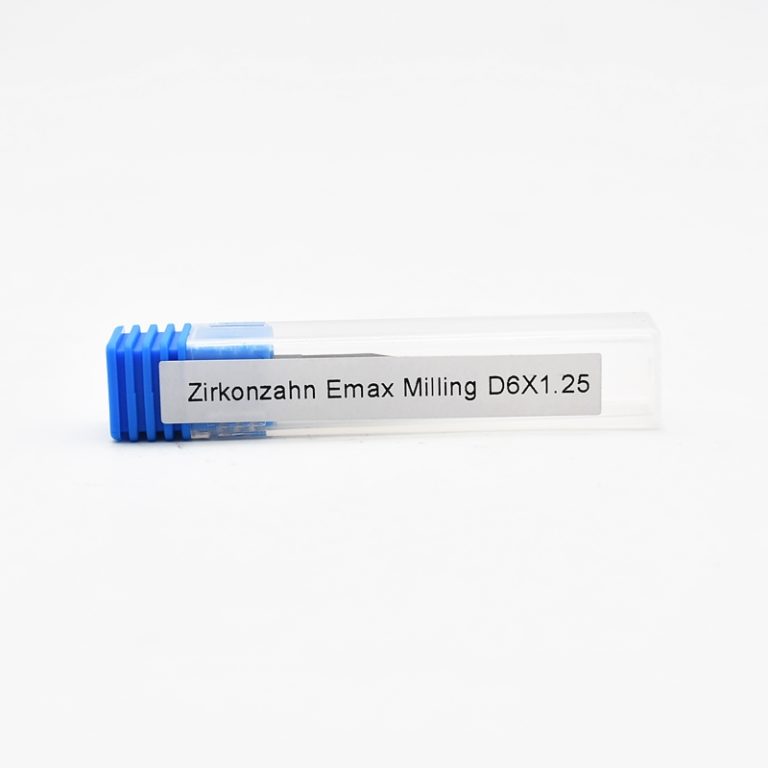

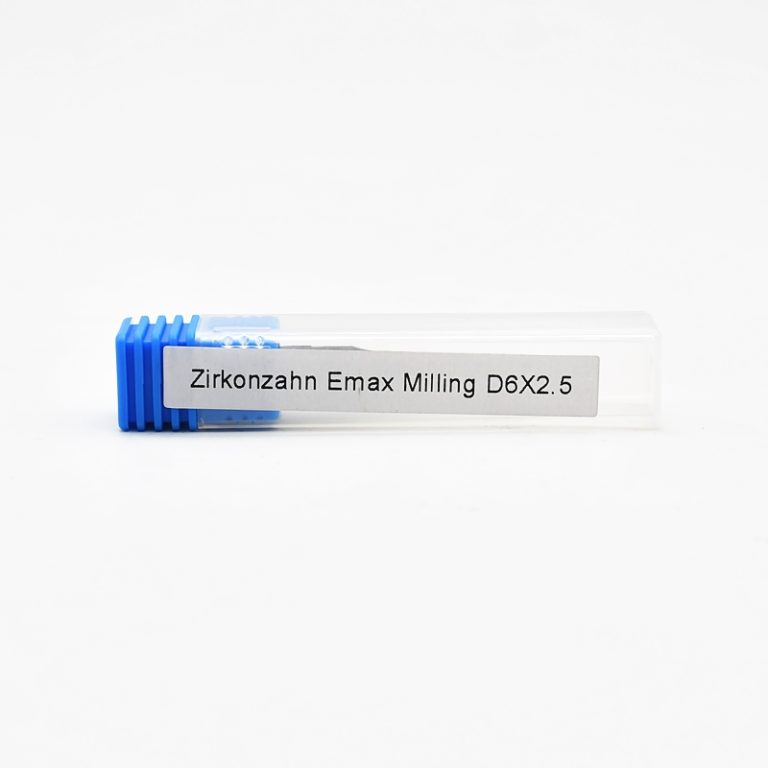

Head Diameter: 0.6/1.25/2.5mm

Shank Diameter: 6mm

Overal length: 50mm

Zirkonzahn M1wet milling burs are high-performance cutting tools designed for processing glass ceramic materials. They are widely used in dental CAD/CAM systems for manufacturing dental restorations such as all-ceramic crowns, veneers, inlays, etc. It is designed specifically for the Zirkonzahn M1 wet milling system to ensure seamless cooperation, improve processing stability and efficiency. When used with coolant, it can reduce the temperature during the milling process, reduce thermal damage and extend the service life of the burs.

Zirkonzahn M1 wet milling burs can accurately mill glass ceramic materials, reduce cracks and edge collapse during the milling process, and ensure the integrity and strength of the restoration. The burs can maintain consistent cutting results during long-term use, effectively improving work efficiency. In a wet milling environment, the burs can keep a low milling temperature to avoid thermal damage. Designed specifically for Zirkonzahn’s CAD/CAM system and wet milling equipment, it is suitable for high-precision, multi-functional dental restoration processing, and can optimize milling effects and processing accuracy.

We provide one-stop solution for dental laboratories. Please feel free to send us an email. You will receive a reply as soon as possible.

Copyright © 2024 XANGTECH Dental Manufacturer And Supplier | All Rights Reserved.