The Evolution of CAD/CAM Technology in Dentistry

The Transformation of Dental Practices

CAD/CAM technology has emerged to integrate digital workflows at dental practices. The transformation enables accurate and efficient manufacturing of dental restorations, improving patient results and satisfaction. Thus, CAD/CAM machines integrate the design part along with the manufacturing which would save time and create more accurate restorations. The design and manufacturing process is simplified, requiring less time and effort to restore patient restorations and greater accuracy is obtained.

How CAD/CAM Machines Enhance Efficiency

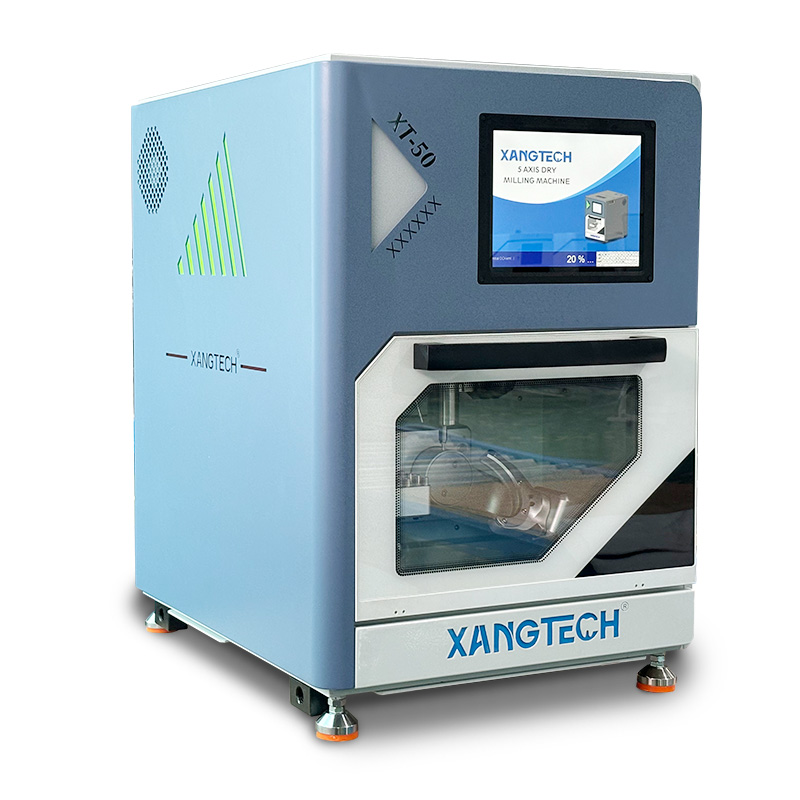

Implement CAD/CAM machines to enhance the functions of your dental laboratory. XANGTECH’s with their XT 50 milling machine, for instance, comes with a power-off resume function, meaning a milling process picks up right where it paused in the event of an interruption. It reduces downtime and prevents unnecessary processes.

Innovations in Dental Milling Processes

The innovations in the dental milling processes that have developed in recent years have been instrumental in pushing the capabilities of CAD/CAM machines. The vertical cutting capability of the XT 50 at an angle of 90 degrees represents such an innovation, taking the form of detailed tooth enamel-type textures that enhance the esthetic quality of prosthetic restorations. Furthermore, its large B-axis rotation range, allows complex implants to be fabricated.

Exploring Machinable Ceramics in Dentistry

Characteristics and Advantages of Machinable Ceramics

Machinable ceramics have high value for their superior strength, biocompatibility, and aesthetic appearance. These materials are able to endure the mechanical forces of mastication while being natural-looking. These properties enable precise shaping and customization to address specific patient requirements in an array of dental applications.

Applications of Machinable Ceramics in Dental Restorations

Machinable ceramics have been used in dentistry for crowns, bridges, veneers, and implant abutments as these materials are strong and simulate of lifelike appearance. This capacity to be milled with precision through the usage of proficient CAD/CAM machines, such as the XANGTECH XT 50, results in restorations that fit exactly in the oral cavity, enabling functional activity and aesthetics.

Challenges and Solutions in Utilizing Machinable Ceramics

One of the problems when machining ceramics is their brittleness and this limits their industrial process. Fortunately, advanced milling technology like that of XANGTECH’s XT 50 machine- the machine comes with a C-type clamp that enhances the usage of the materials by about 20%- can solve this dilemma. Hence, it saves wastage along with lowering the expenses incurred on the material.

The Role of CAD/CAM Machines in Dental Milling

Precision and Accuracy in Dental Milling with CAD/CAM

The secret behind the high precision and accuracy of dental milling is CAD/CAM machines. The XANGTECH XT 50 machine has a machining accuracy of 0.01mm, which means the dental restorations can fit perfectly in the correct position inside the human mouth.

Workflow Optimization through CAD/CAM Integration

Although CAD/CAM technology reduces manual interventions and errors, making the workflows smooth and seamless. Within this workflow, the XT 50 further facilitates this integration through automated resumption after halts, thus streamlining processing and enabling quicker turnaround times for dental restorations.

Impact on Patient Outcomes and Experience

Enhancing Patient Satisfaction with Custom Solutions

CAD/CAM machines in dentistry have revolutionized the art with a unique promise of the most tailored solutions which are sure to derive satisfaction for the individual. One such critical component is the XANGTECH XT 50 milling machine that delivers exact milling that ensures restorations are a perfect fit to not only the natural aesthetics and function but also the unique demands of each patient. Such customization ensures enhanced patient satisfaction in terms of having restorations that not only perform well but also aesthetic restoration to neighboring dentition.

Reducing Treatment Time and Improving Comfort

Perhaps the most significant benefit of CAD/CAM technology is the decrease in the time it takes for treatment. This offers dental labs a combination they both have long been needing, as in the past efforts to speed up restorations would generally result in lower quality; with the XT 50 milling machine, the new major function streamlines the fabrication process so that restorations can be finished at a much faster speed, which does not sacrifice quality. That makes it more comfortable and convenient for patients due to fewer visits and shorter chair times. With this efficient, continual function of the power-off resume feature of the XT 50, dental prosthetics can be produced without delays.

Long-term Benefits for Dental Health

CAD/CAM milling machines have exceptional accuracy, and can, therefore, provide long-lasting benefits to dental health. The restorations are made with the help of machinable ceramics using futuristic machines like the XT 50, highly durable, and bio-compatible, the chances of a future complication are very less. These restorations, which ensure a perfect fit, increase oral health by reducing strain on surrounding teeth and tissues.

XANGTECH’s Contribution to Advanced Dental Solutions

Overview of XANGTECH’s Innovative Products

XANGTECH is known for its innovative method when it comes to dental solutions and provides a wide selection of products that cater to the needs of modern-day dentistry. What beats them in this area is their attention to detail and a sector’s higher technology level. This sets them apart as some of the leaders in the field due to their focus on precision engineering and advanced technology.

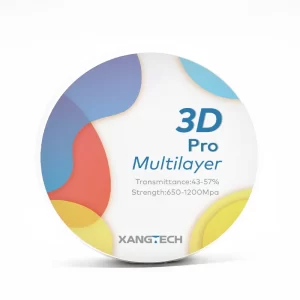

Dental Zirconia Blocks and Their Benefits

High-quality dental zirconia blocks for strength, durability, and aesthetic — XANGTECH such blocks are perfect restorations imitating natural tooth structure along with excellent masticatory load performance. These zirconia blocks can be accurately milled into crowns, bridges, or veneers to exact tolerances when used with XANGTECH’s XT 50 milling machine.

Other Cutting-edge Materials Offered by XANGTECH

Beyond zirconia blocks, XANGTECH has a range of advanced materials for different dental applications. This pertains to machinable ceramics which offer unique mechanical properties coupled with an ease of processing. With the XT 50 and multi-spectrum materials line providing solutions for every patient, XANGTECH keeps the dentist covered with the most comprehensive solutions for their advanced milling machines.

In conclusion, the high-end versatility that CAD/CAM machines provide makes them indispensable modern tools in dental science that can enable more precision, efficiency, and customized approaches in machinable ceramics applications, such as those that XANGTECH products deliver. Companies like XANGTECH are an important part of digital dentistry; their high-tech products propel innovation to the point where clinicians benefit from improved clinical outcomes and patients enjoy improved satisfaction.