Menu

Menu

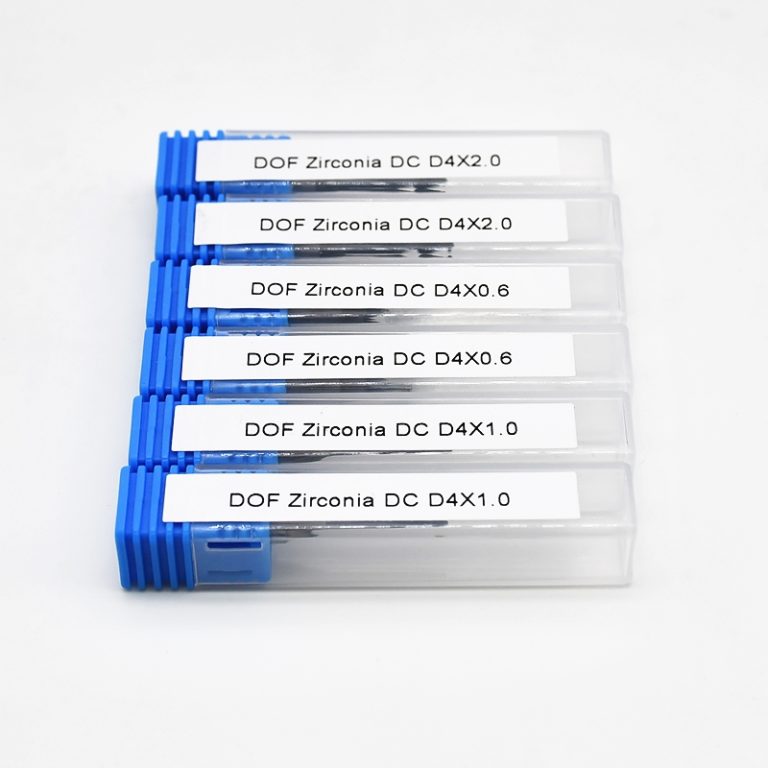

Dof milling bur is made of high-quality carbide or diamond materials, and uses advanced manufacturing technology to create extremely high cutting accuracy, ensuring smooth and lossless results during tooth preparation, restoration adjustment and polishing. The bur is suitable for processing a variety of dental materials, including metals, ceramics, composite resins, etc. The surface is specially coated to improve wear resistance and service life, while the optimized design reduces vibration and improves operating comfort and stability.

DOF milling burs are high-performance cutting tools designed for DOF brand dental CAD/CAM equipment. They are widely used in the processing of denture restorations, including the production of crowns, bridges and complex structure models. Made of high-quality carbide or advanced coating materials, DOF milling burs have excellent hardness and wear resistance, can maintain stable performance under high speed and high load conditions, and achieve high-precision cutting processing.

DOF milling burs are highly compatible with DOF brand milling machines (such as DOF SHARP series, CRAFT series), optimize cutting paths and processing efficiency, and are suitable for common dental materials such as zirconia, cobalt-chromium alloys, resins, and wax materials. Its tool types are complete, including roughing, finishing, grooving knives, etc., which can meet multi-stage needs from roughing to fine processing.

With ultra-high processing accuracy, smooth cutting effect and long service life, DOF milling burs are an ideal choice for high-end dental laboratories and professional processing centers, providing reliable tool support and high-quality processing experience for dental restoration production.

We provide one-stop solution for dental laboratories. Please feel free to send us an email. You will receive a reply as soon as possible.

Copyright © 2024 XANGTECH Dental Manufacturer And Supplier | All Rights Reserved.