Menu

Menu

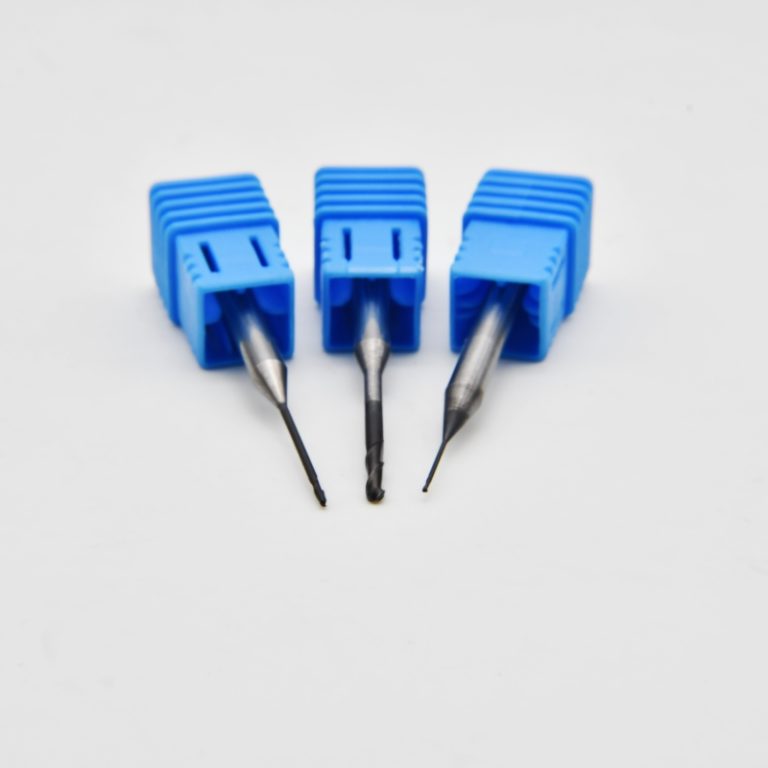

Roland zirconia milling burs help dental professionals create high-quality dental restorations with their excellent cutting performance, durability and high precision. Combined with digital technology, Roland zirconia milling burs play an important role in improving productivity, precision and customization.

Shank diameter: 4mm

Head diameter: 0.3/0.6/1.0/1.5/2.0mm

Overall length: 50mm

Material: Tungsten Carbide

Drill Type: DC/DLC

Application: For zirconia block carving

Roland zirconia milling burs are widely used in dental restorations, especially in the processing of zirconia materials. The diamond coating and diamond-like carbon coating used on these burs give them a long service life and keep them sharp even under high-intensity working conditions. The precision cutting of these burs ensures accurate cutting on zirconia materials, reduces thermal damage during processing, and ensures the smoothness and fineness of the restoration surface.

XANGTECH Roland zirconia milling burs can work stably at high speeds and high pressures, providing efficient cutting performance. Even when processing hard zirconia materials, they can maintain a smooth cutting process, reducing thermal damage and surface cracks.

XANGTECH Roland milling burs are 100% compatible with DWX-52D/DWX-52DCi/DWX-42W.

XANGTECH Roland dental milling burs are high quality burs with extremely high wear resistance. DLC coated bur can drill 150 to 200 units zirconia crown. Diamond coated bur can mill 400 to 500 units zirconia crown.

We provide one-stop solution for dental laboratories. Please feel free to send us an email. You will receive a reply as soon as possible.

Copyright © 2024 XANGTECH Dental Manufacturer And Supplier | All Rights Reserved.