Menu

Menu

Rotation axis working angle: A:360°B:+35°-91°

Spindle speed: 0-60,000rmp

Power: 1.5KW

Rated working pressure: 6.0-7.5bar (anhydrous, oil-free)

Machining accuracy: 0.01mm

voltage: 220-230V

tool magazine: 10mm

Machinable material thickness:10-30mm

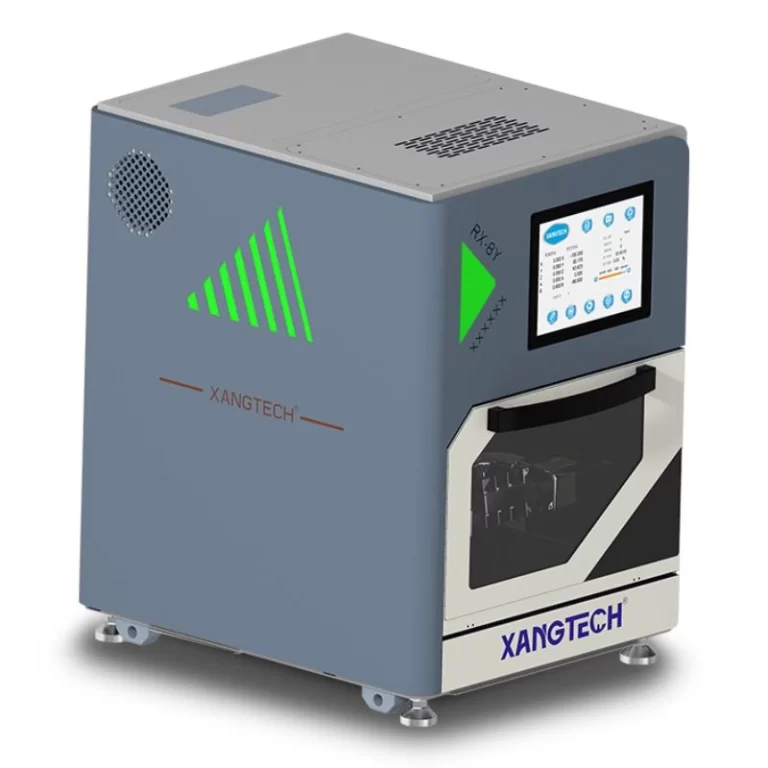

XANGTECH XT 50 milling machine is designed to meet the rigorous demands of contemporary dental laboratories, maximizing both productivity and precision. Its power-off resume function ensures uninterrupted operation by automatically resuming milling tasks after unexpected stops, thereby preventing redundant processes and enhancing overall efficiency. Ideal for anterior milling, the 90-degree vertical cutting feature facilitates detailed enamel-like texture finishes, producing high-quality prosthetic restorations.

It’s B-axis offers an extensive angular range of +350° to -910°, enabling precise fabrication of complex, large-angle implants. Its C-type clamp optimizes material usage, increasing utilization by 20%, which significantly reduces waste and lowers material expenses. Incorporating advanced technology, the XT 50 ensures accurate and consistent milling outcomes. Streamline your laboratory workflow, minimize processing times, and deliver superior dental restorations with the precision-engineered XANGTECH XT 50 milling machine.

1. Automatically continue processing after interruption, improve processing efficiency

2.90 degree vertical cutting, convenient processing, finished product details are more perfect.

3. Large angle of B-axis can process large angle implants.

4.C-type clamp can increase the material utilization rate by 20%, saving dental materials.

We provide one-stop solution for dental laboratories. Please feel free to send us an email. You will receive a reply as soon as possible.

Copyright © 2024 XANGTECH Dental Manufacturer And Supplier | All Rights Reserved.